|

Tony Made Machinery Co.,Ltd.

|

Wood pellet mill machine

| Price: | 22500.0 USD |

| Payment Terms: | T/T,L/C,WU,Money Gram |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

the materials.such as wood,woodchips,pine,mahogany,rubber tree,rice husk,pennisetum,wheat/corn straw,cotton stalks,alfalfa grass,bagasse.

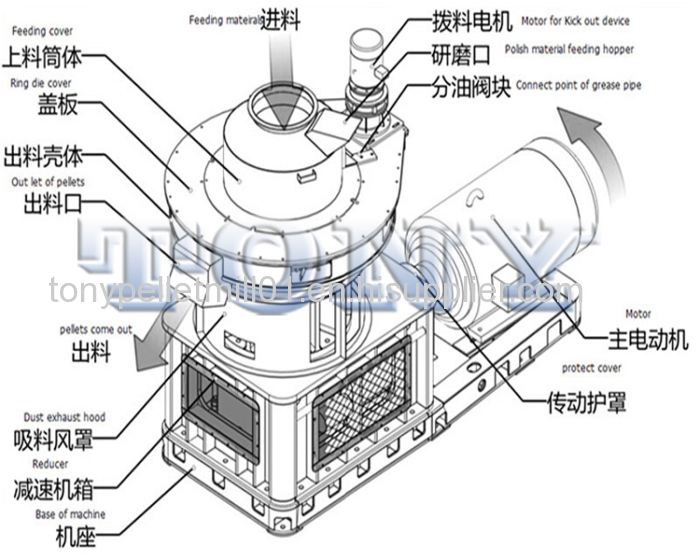

Vertical Type Pellet Making Machine/Biomass Fuel Pellet Press

Brief Introduction of biomass Fuel Pellet Press

TONY biomass pellet making machine is a new biomass fuel production machinery by using crushed sawdust . Compared with the old machine, it obsorbed the essence of horizontal ring die and flat-die pellet machine, solved the insufficient pressure, die crack problems of horizontal ring die pellet machine, and overcame the small capacity, high failure rate of flat die pellet machine.

Product introduction of biomass pellet making machine

Double-layers Ring Die

All kinds of pellet machine only have 1 die(ring die).

Material: alloy, stainless steel

Life time: 3000-4000hours

1,The professional heat treatment processing technology can make its hardness above HRC62.

2. Vertical Ring die, feeding vertically.

3,. Double-lay die, dual use. When one side is damaged, turn over and use the other side.

4,the compression ratio can be custom made

Rollers of biomass pellet mill machine

1.Number of rollers:2 pieces

2,Die fixed, rollers running, materials centrifugal and evenly distributed around.

3,Structure:roller shell and bearing

4,Working life of rollers:1500-2000 hours

Spindle of biomass pellet mill machine

1,Our main shaft is forged.

2,no air insde the main shaft while being forged

3,hard to be broken while high-speed running

Motor of biomass pellet mill machine

Efficiency high overload capacity, low noise, small vibration

reliable structure.

Rated Voltage 380V Rated Frequency 50HZ

400V 415V 420V 440V 690V 1140V and 60HZ ect.

Can also be made according to customers' requirements.

Reducer

1.Reducer transmission.

2.High efficiency,easy maintain and repair.

Self-lubrication System

Lubricating rollers to make the pellet press machine continuously run for 24 hours(using lubricating grease).

It also has the warning function when high pressure/temperature or low pressure/temperature appear.

The Features of biomass pellet making machine

1.Vertical hopper: This design can avoid the raw material be stuck in granulating room.

2.Cooling system: As the pelletizing process will generate high temperature, it will lower the service life of die and bearing.Cooling system are considering this situation and avoid it happened.

3.Double-layer dies: This design increase the efficiency of pellet making,reduce clients cost.

4.Bearing: High precision, high speed, low noise, long life

5.Unique automatic lubricating system: Which lubricate the bearing, dies and rollers ,increase the produce efficiency and reduce energy consumption.It can work continuous 24 hours.

The raw material of biomass pellet making machine

Raw material: wood, waste wood and straws, etc. such as woodchips(palm, pine white pine, mahogany, pinus sylvestris, rubber tree), bamboo shavings, rice hust, seeds shells, peanut shells, halm, pennisetum, wheat straw, corn stalk, cotton stalks, alfalfa grass, bagrass, palm fiber, waste paper, non-physical material.

Size: Less than 5mm (All the raw materials must be crushed into sawdust before going

to wood pellet machine.If not, you may need a wood chipper, wood crusher.)

Moisture: Generally, 10-15% is best for producing good quality wood pellet.

Spare Parts of biomass pellet making machine

Rollers | Be made of alloy steel and stainless steel with longer service time:2500-3000 hours. |

Ring Die | Double layers with longer service time: 1000-1500 hours; |

Motor | A.Efficiency high overload capacity, low noise. |

Driving method | Reducer connected with motor directly. |

Working method | pressing from the inside to outside, centrifugal force with extrusion |

Automatic lubrication | A.Independent lubrication |

Technical Data of biomass pellet making machine with Reducer Transmission

Tech Datas of Ring Die Pellet Machine With Reducer Driver | ||||

Model | Power(KW) | Capacity(T) | Weight(T) | Size(mm) |

TYJ560-II | 90 | 1-1.5 | 6.1 | 2600*1300*2300 |

TYJ720-II | 160 | 1.5-2.5 | 7 | 2900*1300*2400 |

TYJ850-II | 220 | 2.5-3.5 | 14.5 | 3300*1400*3100 |

TYJ920-II | 315 | 3.5-5 | 18 | 3800*1680*3400 |

TYJ1050-II | 360-450 | 5-6 | 23 | 4400*1850*3700 |

TYJ1250-II | 550-660 | 7-8 | 29 | 5100*2000*4050 |

Pellets produted by our biomass pellet making machine

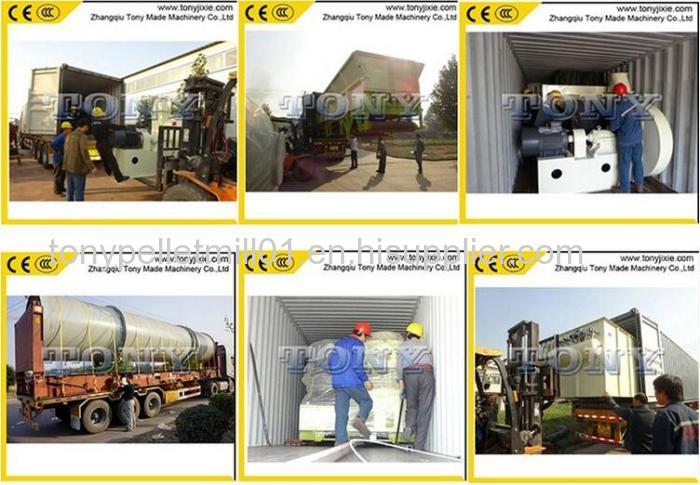

Packing

Sccessful wood pellet lines all over the world

We can also supply the biomass pellet making machine as following:

1.The SKJ Series flat die pellet mill and feed pellet mill with the volume 100kg per hour to 4 ton per hour.

2.The TYJ Series ring die pellet mill with the volume 800kg per hour to 5 ton per hour.

3.The SKJD Series Pellet Mill with Diesel Engine with the volume 100kg per hour to 400kg per hour.

4.The SKJT Series Pellet Mill with Tractor Engine with the volume 80kg per hour to 400kg per hour.

5.straw Hammer Mill

6.Wood crusher

7.Wood chipper

8.Drum dryer

9.Packing machine

10.Whole pellet making production line from capacity 0.5 ton per hour to 20 ton per hour.

ZHANGQIU TONY MADE MACHINERY CO., LTD is a professional manufacturer and exporter engaged in the research, production, sale and service of Biomass wood pellet line, wood pellet mills, feed pellet mills, grinding equipment, crushing equipment, drying equipment, cooler and other screening, conveying equipment.

TONY has agents in Germany, France, Serbia, Italy, Bulgaria, Thailand, Malaysia, Vietnam, Croatia, Serbia who can supply machines timely with competitive price and also do better after-sales service.

When you tell me the information as following, I can offer you very specific and targeted advice.

| what capacity would you prefer? | The capacity for vertical ring die pellet mill model. |

| What is your raw material ? | According to different raw material(such as hard wood, softwood, straw, rice husk), capacity is different. |

| What is your raw material size? | Best size for pressing high quality pellets is 3mm. |

| What is the moisture of your raw material? | Better to be 10-15%. |

Testing of biomass pellet making machine

CE Approved

-24 Hours Online Service.

-Inquiry will be replied within 2 hours.

-All-the-way tracking service offered from placing order to delivery.

-Free training for operation, debugging and daily maintenance.

-We can provide professional guide installation.

-One year warranty and all-round after-sales service.

-Customized design and flow chart are available for our clients.

-Independent R&D team and strict & scientific management system.

Any more information you want to know, please contact me freely.

Miss Amy(Sales Manager)

Skype: tonypelletmill_01

Mobile/WhatsApp: + 86 15853148288

QQ: 2975663765

Email: Pelletmill01@tonyjixie.com/tonypelletmill01 AT hotmail.com